At this moment, various parts, kits and modules are on its way to me by mail. That will take some time. Furthermore, I don't have very much time for hobbies at the moment. So it will take some time before an update will appear here!

As soon as there is something new to tell, I will let you know in the SDRplay FB group.

My latest project is building two SDR's in one, ruggedized case for serious outdoor and field work. In my opinion, Airspy SDR and the SDRplay are modules - not 'equipment'. Just fit the modules in a serious case along with some useful extra's and then you finally get 'equipment' that is ready to use under different circumstances. Measures are taken to avoid unwanted interference such as local RFI, QRM from home appliances and noise from USB host power sources.

woensdag 24 juni 2015

maandag 22 juni 2015

INTRODUCTION AND GOALS

Building the Thing

This blog is entirely dedicated to one project: building both the Airspy SDR (and its future SpyVerter) and the SDRplay in one solid enclosure.

Why two SDR's?

Every SDR has its idiosyncrasies. Building two in one case makes it a solid tool with enough hardware on board to fit different needs. And it offers an ultimate opportunity to compare the usability of both SDR's in the field.

The main objectives are:

This blog is entirely dedicated to one project: building both the Airspy SDR (and its future SpyVerter) and the SDRplay in one solid enclosure.

Why two SDR's?

Every SDR has its idiosyncrasies. Building two in one case makes it a solid tool with enough hardware on board to fit different needs. And it offers an ultimate opportunity to compare the usability of both SDR's in the field.

The main objectives are:

* Powering the active devices from separate linear power supplies

and batteries, thus cutting the 5V USB lead; A 4 pole male XLR connector will be used as a DC receptacle;

* Apply as much protection as possible against unwanted

signals such as USB noise and protecting against cables and leads that may work

as an antenna;

* Create a very solid and RF-tight enclosure that can

withstand intensive use in the field and leaves room for future hardware

extensions that need to be placed 'under the hood'.

|

| 'Faraday Cupper Mesh' I picked up at the metal store. Destination still unknown. |

The case

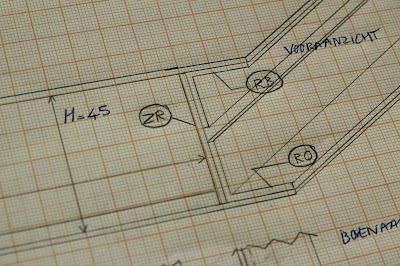

Earlier I crawled the whole internet for readily available commercial

enclosures but none of them fitted my

needs. So I decided to design my own.

The design…

…includes a lot of

room for the units, sidekick devices and possible future extensions;

…is made of aluminium plate, thickness 2mm and aluminium

profiles, angled ½π, sides of 20mm, thickness 2mm;

…will be kept together by stainless steel hexagonal screws and NOT by pegs;

…provides easy access to all areas in the case;

In my country, the frequency domain for wireless microphones is rapidly shrinking because these domains are conquered by 4G networks. Soon I will offer on-location RF surveys and advice production companies (TV and live entertainment) which frequencies are vacant for solid wireless connections.

But I don't want them to look over my shoulder and steal the trick. So I will provide the case with a Russian brand name and model designator, such as 'Vasyljev XTR-320'. Googling this will end up in nothing and nowhere. Or herewhere.

[Update:] More secret whys

There are actually a few more reasons than the ones mentioned above. I love craftmanship. I love ruggedized equipment, as I often see in rude environments such as oil and gas production sites and platforms. I love the fun of fake branding. I love to have choices: either switch on SDRplay or AirSpy mini.

WILL BE CONTINUED HERE!

Abonneren op:

Reacties (Atom)